Waterjet Cutting in Carlisle, Cumbria

Waterjet cutting is a fast growing machine tool process, due to its versatility and capability to cut most types of materials, manufacturers are realizing that there are virtually no limits to what waterjets are capable of cutting. Major benefits of waterjet cutting include; no heat generated structural changes, cold cutting process, virtually burr free cut edges, reduces finishing operations and no material distortion or discolouration.

The range of materials cut by water is considerable; some are listed below, but it is not definite. Norwest will be pleased to discuss any particular requirement and obtain samples for test cutting.

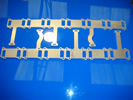

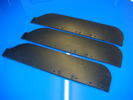

- Examples of Work

- Materials Cut

- Benefits

| Metals |

| Aluminium, Brass, Copper, Duplex, Inconel, Invar, Mild Steel, Stainless Steel, Titanium, and Tool Steel |

| Ceramic Carbide |

| Alumina Ceramic, Carbide |

| Composite / Laminate |

| Carbon Fibre, Fibreglass, Laminates |

| Glass |

| Plate Glass, Soda Lime Silica Glass |

| Plastic |

| Acrylic, Acetal, Nylaron, Nylon, Polycarbonate, Polypropylene, PVC |

| Stone |

| Granite, Limestone, Marble, Slate, Sandstone |

| Wood |

| Hardwood and Softwood |

| Soft Materials |

| Foam, Rubber, Plastics, Synthetic Materials |

Tilt a Jet head allowing accurate virtually zero taper with most materials.

Quality Finish - materials cut with an abrasive jet have a smooth satin like finish similar to a fine sandblasted finish, reducing the need for secondary operations.

Environmentally Friendly � abrasive jets use garnet, as an abrasive garnet is an environmentally safe naturally occurring hard crystal, no noxious gasses or liquids are used in abrasive jet.

Cutting Programmes � can be produced from drawing imported from customers electronic files e.g. DXF, IGES, DWG or digitised templates.